Complete renovation of the Juchlishaus cheese dairy

The Juchlishaus cheese dairy in the municipality of Mühleberg has been renovated and expanded. Located in the production zone in the canton of Berne, it produces 9,500 wheels of Le Gruyère AOP per year, whereas in the past it produced Emmental.

"I was very happy that the producers gave me a lot of freedom and trust in me to participate in the design"

Bruno Wütrich, cheese maker in Juchlishaus

In 1994, the members of the Juchlishaus cheese dairy decided to switch from Emmental to Gruyère. This decision was made partly under pressure from the Swiss Cheese Trade Association, which was responsible for sales at the time. "In retrospect, it was a great opportunity for us," recalls Urs Marthaler, producer and president of the dairy company.

25 years after the switch to Gruyère, the entire cheese dairy had aged. The plant was in urgent need of renovation and the conditions in the cellars were very difficult, which led to increasing quality problems. The dairy company was ready to invest in the future. They looked at all the options, from renovation to new construction. "Then Lady Luck smiled on us," says Urs Marthaler. "The restaurant opposite the cheese dairy had closed, and the owner was interested in selling the land on which the car park for his customers was located, right next to the cheese dairy. It was a perfect site for a new cellar." The decision was therefore made in favour of a complete renovation.

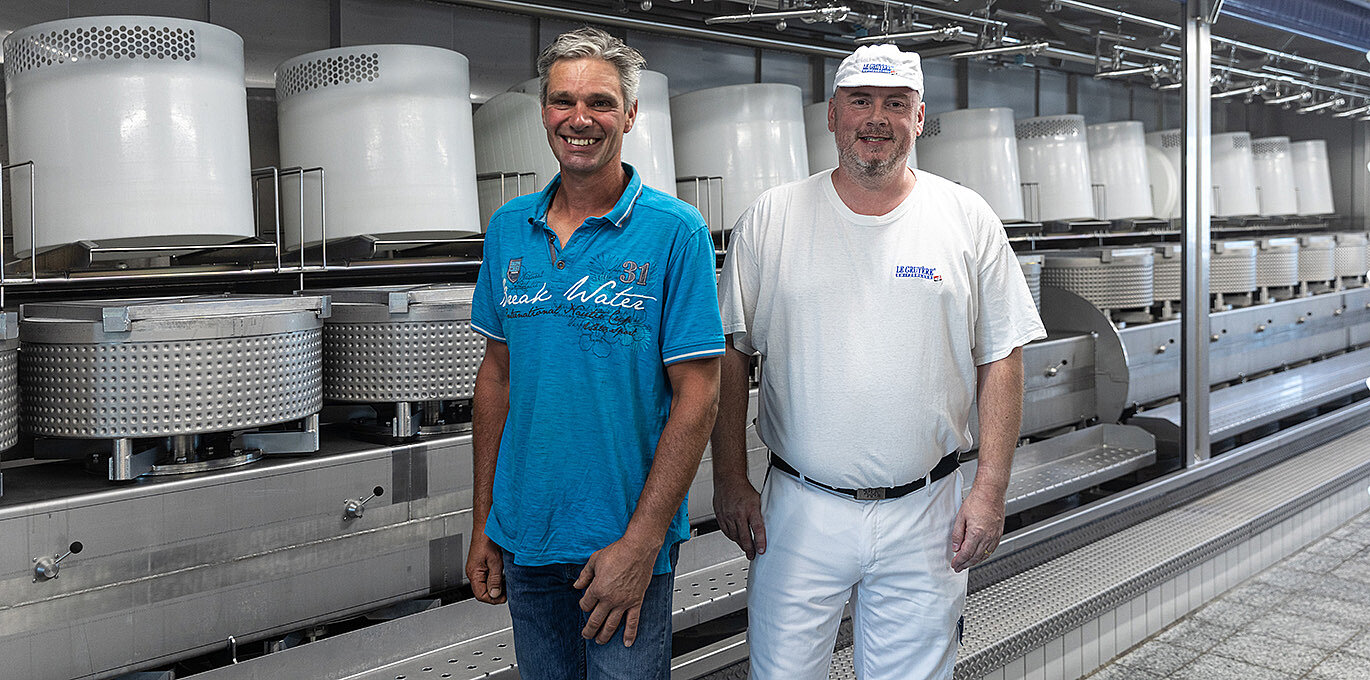

In 2016, Bruno Wüthrich was appointed as the new cheesemaker and moved into the Juchlishaus cheese dairy. It was precisely at this time that the plans for the transformation became a reality. Thanks to a successful collaboration between the architect, the cheese dairy board and the cheesemaker, the project became a reality. "I was very happy that the producers gave me a lot of freedom and trust in me to participate in the design," says Bruno Wüthrich. "All my proposals were guided by the desire to produce a high-quality Le Gruyère AOP, to optimise the processes and thus the working conditions in the cheese dairy."

The work began with the construction of an extension to the cheese dairy, so that production could be maintained in the existing dairy as long as possible. Therefore, the extension for the new cheese machines and the milk preparation room were built first. While the concreting, hammering and screwing work continued on one side, the production of Le Gruyère AOP could continue on the other side until December 2019. "We had to stop production for only four and a half months and deliver our milk to the industry," says Marthaler. "Unfortunately, it was not possible to process the milk of our 18 producers in other cheese dairies. That's why we are very happy and proud that production was able to restart on 18 May 2020."

The final step was the construction of the new cheese cellar. “Previously, we were short of space and could only store the wheels for two months," recalls Bruno Wüthrich. "After that they were sent to FROMCO SA in Moudon. Today, the new cellar can accommodate 4,500 wheels of cheese and we look after our Le Gruyère AOP on site during the entire maturing process. This is a great satisfaction."

The end of the renovation work was in November 2021. The improvements were felt very quickly. "We were very lucky," says the cheesemaker. "From the very first day after the work was completed, we produced a Le Gruyère AOP of very good quality. I can rely on the producers who deliver good milk and with whom I have good communication. The transformation of the cheese dairy was a joint project that involved all of us, the milk producers, the cheesemaker and the employees of the cheese dairy who do an excellent job every day. Indeed, our common interest is to produce a high quality Le Gruyère AOP, which allows us to get a good price for the milk. Only together can we successfully master the future."