The Bouloz-Porsel cheese dairy

Several cheese dairies have recently embarked on major projects: new buildings, extensions or renovations.

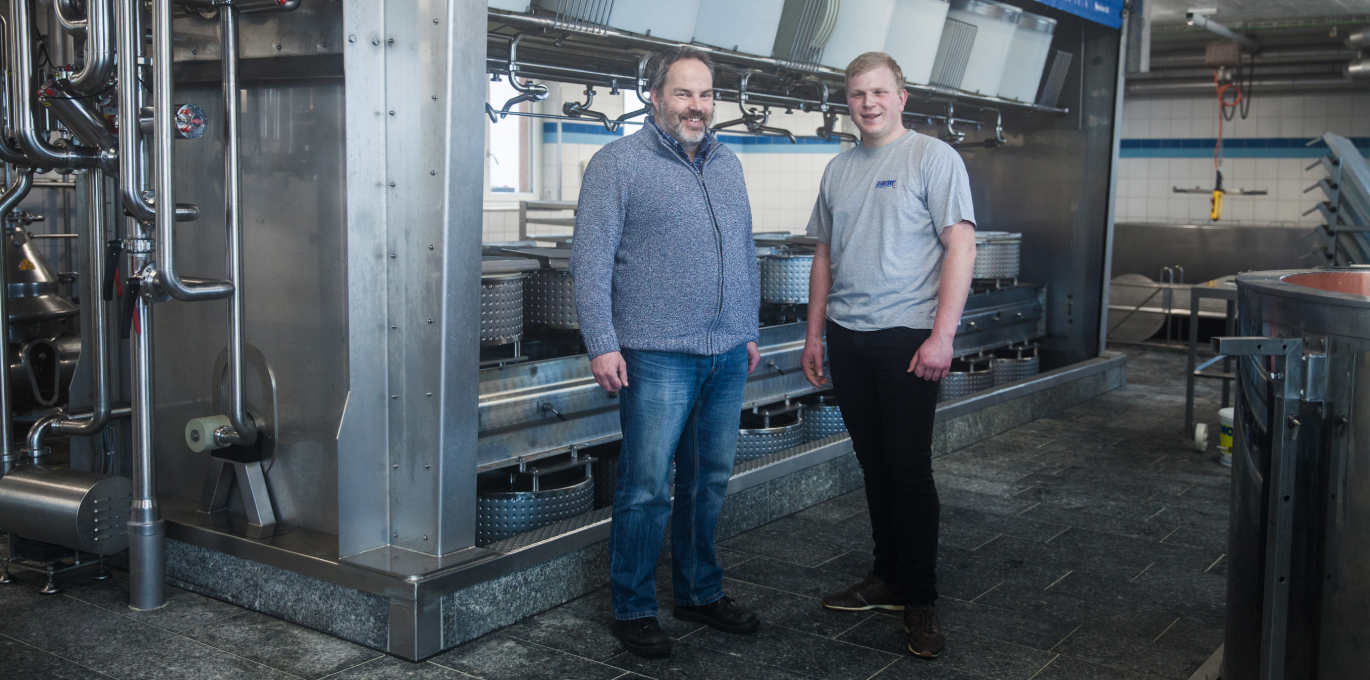

The Bouloz-Porsel cheese dairy in Glâne is a family business. Together with his father Roland and their two employees, Anthony Pittet produces 277 tonnes of Gruyère AOP per year. Although the building housing the dairy is now 27 years old, the dairy itself is brand new. The cellars and facilities have been brought up to date to meet the latest standards and obtain Fromarte certification.

“Even with a lot more milk, we save a lot of time thanks to the robot in the cellar and the automation of certain tasks that are not essential to the production process, such as cleaning.”

Anthony Pittet, cheese maker

Until 1992, the villages of Porsel and Bouloz had two dairies. They merged to build the current dairy. Roland Pittet, Anthony's father, was already a cheesemaker in Porsel at the time. Last year, in order to comply with Fromarte standards, the dairy company decided to enlarge the cellars, change most of the facilities, create a larger milk delivery area and, taking advantage of the work being done, expand the shop.

"We had always maintained our facilities to the best of our ability. Everything was functional, but it was 26 year-old technology," explains Fabien Thürler, President of the Bouloz-Porsel dairy and cheese company. What's more, the cheesemakers now receive much more milk and make more cheese than when the facility was built. Over the years, in addition to the production of Gruyère AOP, they began to produce Vacherin Fribourgeois AOP, raclette and industrial milk. Everything was becoming far too small. "We needed more space. It was starting to cost us a lot of money," says Thürler.

Anthony Pittet has been an employee of his father since 2011. He decided early on to follow in his father's footsteps. Since the end of compulsory schooling, he has always worked in the dairy. When his father decided to retire it made sense for him to take over the family business, in agreement with the cheese company. "I didn't think that the renovations would change the day-to-day working techniques so much," he confides.

New technologies have now found their place in the dairy. "Even with a lot more milk, we save a lot of time thanks to the robot in the cellar and the automation of certain tasks that are not essential to the production process, such as cleaning." Despite this, the cellar robot is not as capable as a human and requires the help of the cheesemakers. If a wheel is misaligned, it is not able to turn it over. For lane changes, the cheesemakers have to reposition the robot manually. So there is less daily work, but more supervision in order to maintain the quality of the cheese. The Gruyère AOP finishes its affinage at Lustenberger and Durst in Heitenried.

In addition to the updates to the dairy, the whole team wanted to have a larger shop that would sell local products. "We, the milk producers, also make other quality products. It was important that we could also offer them to the people of the region."